Quality Department

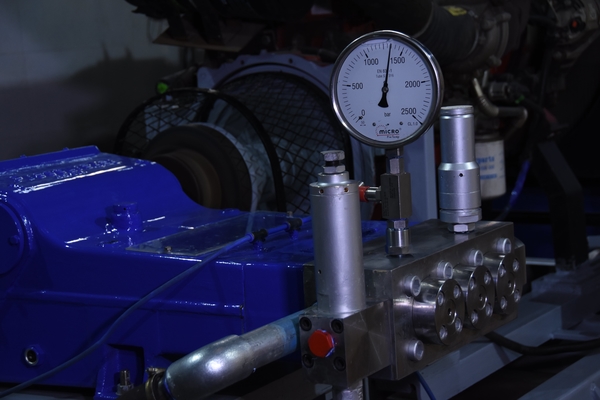

PressureJet accord top priority to quality of pumps that it manufactures. Each pump/system thoroughly tested against quality parameters, before it is dispatched to the client. Considering the range of high-pressure pumps in its portfolio, PressureJet has 5 SCADA based Computerized Test Benches, which are integrated to manage, monitor and control the entire test process of all 5 pumps simultaneously.

The 5 test benches cater to the following power requirements:

- 3 HP to 30 HP

- 40 HP to 60 HP

- 75 HP

- 100 HP to 120 HP

- 150 HP to 200 HP [Engine Driven as well as Electric Motor Driven]

The testing facility has Siemens make high accuracy flow measuring devices, E+H make Pressure Transducer, Grundfos suction-booster pump, temperature sensors, vibration meters, noise level meters and pneumatically activated pressure regulating valves, To support 50 to 500 long hours of full load, continuous hours of trial, PressureJet has a captive recirculating cooling system and 1 100,000 liters of underground clean water tank.

Apart from in-person inspection of pump and a system, PressureJet also provides online access to view the pump performance during inspection. It enables clients to view the actual performance of their pump through IP cameras in real-time.

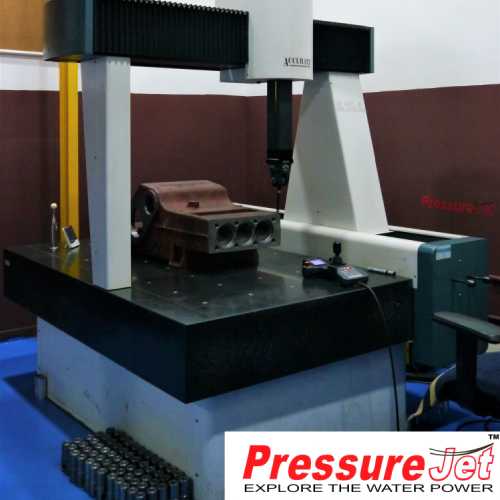

PressureJet is equipped with the most advanced quality checking equipment among all high pressure plunger pump manufacturers in India. This enables the company's quality to stand head and shoulders above competitors. PressureJet believes in maintaining international Quality standards for its products.

To the end, the company has invested over INR 10 million in establishing its Quality Checking department and checks all critical precision engineering components of the pumps in a controlled environment. It currently uses 257 sophisticated and different quality checking instruments across the entire manufacturing process-right from procurement of raw materials to final inspection and testing of pumps before dispatch.

PressureJet is the only High Pressure-Pump manufacturing company in India that has the highest number of quality checking instruments that are procured, maintained and regularly used to ensure.